Source: Kunshan TES Electronic Technology Co., Ltd.2021-04-13

Most porfessional and industrial thermal printers will let you choose between two thermal printing methods: thermal transfer and direct thermal.

Both printing methods require a thermal print head that applies heat to the surface being marked. The print head consists of tiny heating elements that heat up the selected areas to produce the desired print images. Their printing resolution is determined by the size, number and arrangement of heating elements, specified in dots per inch( which means dpi, 203 dpi, 306 dpi or 600 dpi). The higher the dpi is, the higher resolution and quality is.

The difference between the two methods is in the surface that is heated by the print head: thermal transfer printing uses a wax- or resin-based ribbon that transfers ink onto the media when heated. While direct thermal printing uses heat-sensitive labels or papers which blacken where they are heated directly.

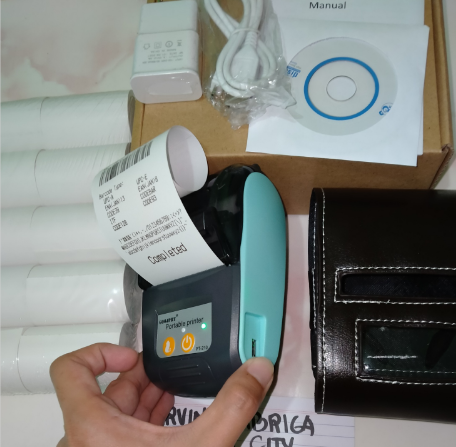

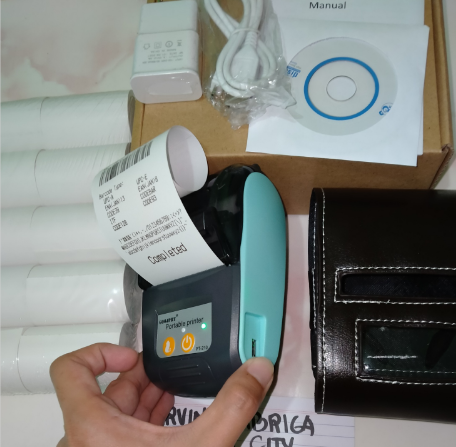

We have 2 kinds of thermal printers. One is thermal receipt printers and thermal label printers, which is using direct thermal printing method.

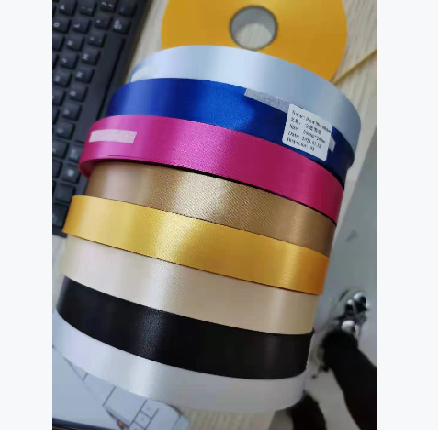

The other is satin ribbon printers, which use thermal transfer printing, tansfer foils onto ribbons when heated. D4022 is 203 dpi, D4032 is 306 dpi.

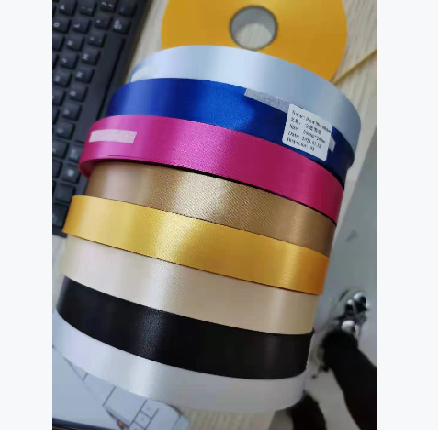

ribbons and foils as below:

Here are some product application of satin ribbon printers:

Flower ribbon:

Funeral ribbon:

Gift packaging ribbon:

Ceremonial ribbon: